Hydraulic hoses do more than transfer fluid — they ensure your entire system operates safely and efficiently. Using the wrong hose can lead to reduced performance, increased wear on other components, and dangerous blowouts. According to the International Fluid Power Society (IFPS), incorrect hose selection is one of the leading causes of hydraulic failures in the field. Selecting the right hose for your application is essential for avoiding costly downtime and equipment damage.

Key Factors to Consider When Selecting a Hydraulic Hose

1. Size:

Proper hose size ensures adequate fluid flow and prevents overheating or cavitation. Undersized hoses restrict flow, while oversized hoses can reduce system responsiveness. Always consult your equipment’s specifications to match hose diameter to flow requirements.

2. Pressure Rating:

Hoses must be rated for pressures greater than your system’s maximum operating pressure. This includes accounting for spikes or surges during operation. Using a hose with too low a pressure rating can lead to catastrophic hose failure.

3. Material:

Hydraulic hoses are available in a variety of materials, each suited for different conditions: – Synthetic Rubber: Highly flexible and resistant to abrasion, ideal for general applications. – Thermoplastic: Lightweight and resistant to chemicals, perfect for mobile or lighter-duty systems. – Teflon (PTFE): Excellent for high-temperature applications and systems that require compatibility with a wider range of fluids.

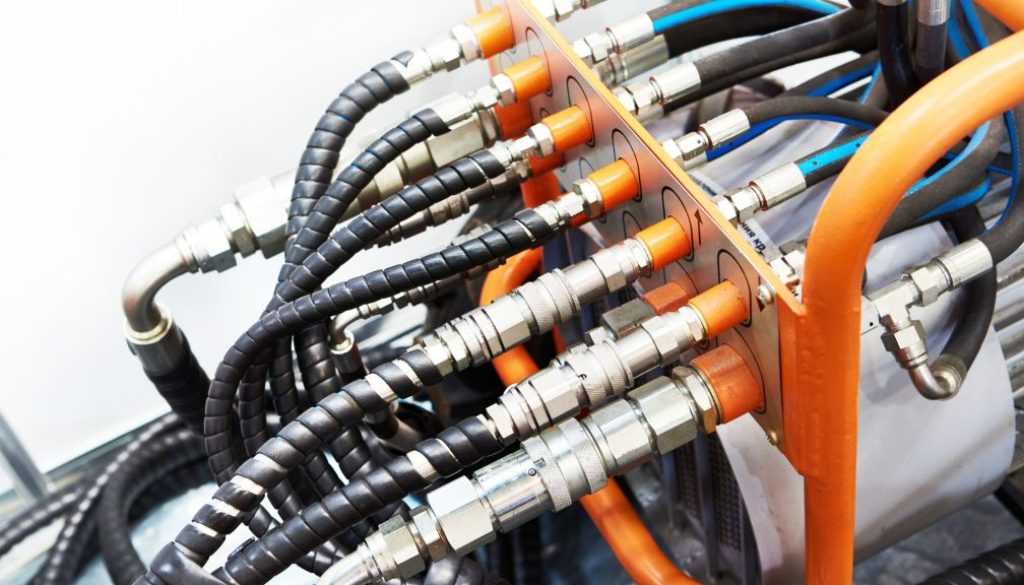

4. Flexibility & Routing:

Consider how the hose will be routed. Hoses in tight spaces or those exposed to constant movement need greater flexibility and protective sleeves to prevent wear.

5. Temperature Range:

Hydraulic systems often operate in extreme environments. Choose hoses rated for both fluid and ambient temperature ranges your equipment will encounter.

What Types of Hydraulic Hoses Are Available?

The market offers a wide range of hoses, each designed for specific uses: – Standard Hydraulic Hoses: Designed for moderate pressures and common applications like construction machinery. – High-Pressure Hoses: Built for heavy-duty equipment in mining, forestry, or manufacturing where pressures are extreme. – Spiral-Wound Hoses: Provide enhanced durability for high-pressure, high-impulse applications. – Braided Hoses: Offer greater flexibility and are ideal for systems with constant movement or vibration.

Understanding the strengths of each type allows you to select the best option for your unique equipment needs.

Benefits of Choosing the Right Hose

Investing time in proper hose selection offers significant long-term benefits: – Enhanced Safety: Prevents blowouts that can injure operators or damage surrounding components. – Improved System Performance: Ensures consistent fluid delivery and reduces strain on pumps and valves. – Reduced Maintenance Costs: Properly chosen hoses last longer, reducing the frequency of replacements and emergency repairs. – Operational Efficiency: Keeps your equipment performing at its best, minimizing downtime and maximizing productivity.

Get Expert Help with Hose Selection

With so many options on the market, choosing the right hydraulic hose can be overwhelming. At BFS Fleet Services, our technicians specialize in assessing your system’s needs and recommending hoses that meet your exact requirements. We provide custom hose assembly and installation services, ensuring your hydraulic system operates safely and efficiently. Learn more about our hydraulic services or book an appointment today.