If you’ve ever dealt with a failing hydraulic system, you know how frustrating and costly it can be. Hydraulic systems power critical truck functions—dump beds, lift gates, cranes, and braking systems. When something goes wrong, operations grind to a halt. But with the right care, you can prevent breakdowns and avoid expensive repairs.

Hydraulics offer unmatched power, smooth operation, and precise control. However, like any hardworking system, they experience wear over time. Contaminated fluid, leaks, or neglected maintenance can lead to performance issues.

Let’s dive into how these systems work, what commonly goes wrong, and how you can fix and prevent hydraulic failures.

Understanding Truck Hydraulic Systems

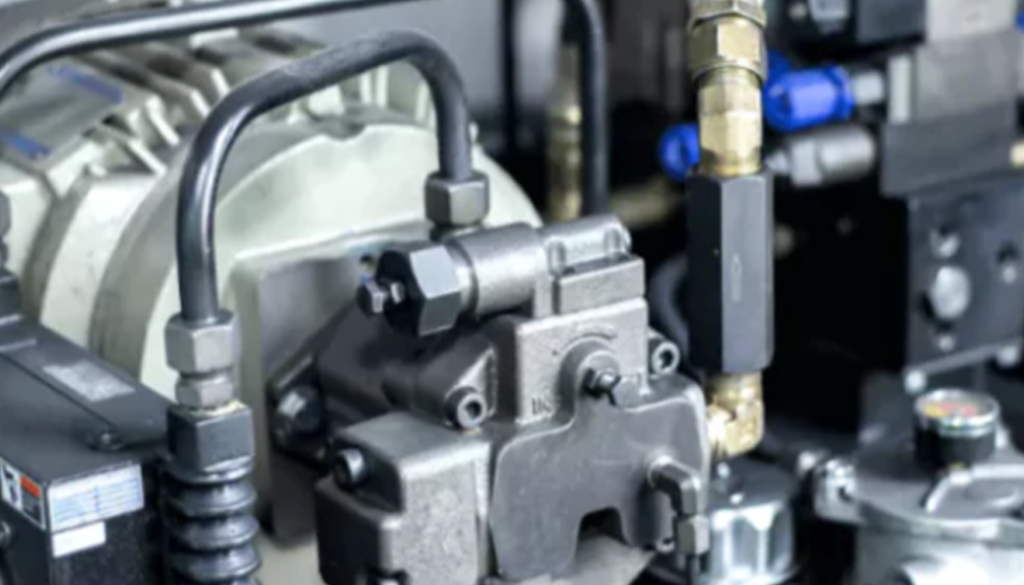

A truck’s hydraulic system uses pressurized fluid to transfer power efficiently. These systems are crucial in applications that require lifting, pushing, or braking. The key components include:

- Hydraulic Pump – Generates fluid pressure

- Reservoir – Stores hydraulic fluid

- Hoses & Fittings – Transport fluid under pressure

- Valves – Control fluid direction and flow

- Cylinders – Convert hydraulic energy into mechanical force

Common Hydraulic System Issues in Trucks

Ignoring minor hydraulic issues can lead to major failures. Here are the most common problems truck owners face:

- Fluid Leaks – Caused by cracked hoses, worn seals, or loose fittings, resulting in pressure loss and reduced efficiency.

- Contaminated Fluid – Dirt, water, or metal particles can degrade the hydraulic system, leading to wear and overheating.

- Pressure Loss – Faulty pumps, leaks, or clogged filters can prevent the system from generating adequate force.

- Overheating – Excessive heat can break down hydraulic fluid, reducing lubrication and system longevity.

- Slow Operation – Weak pressure or air in the system can lead to sluggish movement of hydraulic cylinders.

Troubleshooting Hydraulic System Failures

If your hydraulic system isn’t performing as expected, here’s how to diagnose the issue:

- Check for Visible Leaks – Look for fluid puddles under the truck and inspect hoses for cracks.

- Analyze the Fluid – Dirty or milky-looking fluid signals contamination.

- Test System Pressure – Use a gauge to check if pressure falls within the manufacturer’s recommended range.

- Listen for Unusual Noises – Whining, grinding, or rattling sounds can indicate pump failure or trapped air.

- Monitor Temperature – Overheating may point to low fluid levels, friction, or clogged filters.

Step-by-Step Hydraulic System Repair Process

- Isolate the Faulty Component – Shut down the system and identify the affected area.

- Drain and Replace Hydraulic Fluid – If contaminated, flush the system and use manufacturer-recommended fluid.

- Repair or Replace Components – Swap out damaged hoses, seals, or pumps.

- Bleed the System – Remove trapped air to restore proper function.

- Test the System – Run performance tests to ensure smooth operation before resuming work.

Preventative Maintenance for Long-Lasting Hydraulic Systems

Preventative maintenance is key to avoiding costly repairs.

- Routine Fluid Checks – Monitor levels and change fluid as recommended.

- Inspect Hoses & Seals – Look for cracks, leaks, or loose connections.

- Clean Filters Regularly – Prevent debris from clogging the system.

- Monitor Temperature – Avoid excessive heat exposure that degrades fluid.

- Use Quality Parts – Invest in high-quality components to extend system life.

The Role of a Professional Truck Repair Shop

Some hydraulic repairs require professional expertise. If you notice any of these issues, it’s time to call in the experts:

- Advanced Diagnostics – Detecting issues with precision equipment

- Certified Technicians – Experienced mechanics familiar with various truck models

- Genuine Replacement Parts – Ensuring compatibility and durability

- Hydraulic System Testing – Confirming repairs meet safety and performance standards

Keeping Your Truck’s Hydraulic System in Peak Condition

Taking proactive steps today—such as regular inspections, timely fluid changes, and seeking professional repairs when needed—can help ensure longevity, safety, and reduced downtime for your fleet.

FAQs

1. How often should I check my truck’s hydraulic fluid?

Check fluid levels at least once a month and replace them according to the manufacturer’s schedule.

2. What causes hydraulic system failure in trucks?

Common causes include fluid contamination, leaks, worn-out seals, overheating, and pump malfunctions.

3. Can I repair a hydraulic leak myself, or do I need a mechanic?

Small leaks may be temporarily fixed with sealants, but professional repairs ensure a long-term solution.

4. What are the warning signs of hydraulic pump failure?

Slow operation, pressure loss, excessive noise, and overheating are key indicators of a failing hydraulic pump.

5. How can I prevent hydraulic system overheating in my truck?

Regular fluid changes, keeping cooling systems clean, and avoiding excessive loads can help prevent overheating issues.