Why Ignoring Your Fleet’s Suspension and Alignment Could Be Draining Your Budget

Your Fleet’s Suspension Takes a Beating Every Day—Is It Holding Up?

Your trucks hit potholes, uneven roads, and heavy loads daily—and every mile adds stress to the suspension system.

- A misaligned truck can reduce fuel efficiency by up to 10%.

- Worn-out shocks and struts increase stopping distances and reduce driver control.

- Ignoring suspension issues leads to uneven tire wear, forcing premature replacements.

At BFS Fleet Service, we help fleets detect alignment and suspension issues early, so your trucks run smoother, your tires last longer, and your fuel costs stay low.

Related: Schedule a Fleet Suspension & Alignment Check Today

1. Signs Your Fleet Needs a Suspension & Alignment Check

Your trucks may seem fine today, but these warning signs indicate it’s time for an inspection:

- Truck pulling to one side – Misalignment increases fuel consumption and tire wear.

- Uneven tire wear – If your tires aren’t wearing evenly, your suspension is likely off.

- Excessive bouncing after hitting bumps – Worn shocks and struts cause instability.

- Steering feels loose or unresponsive – Suspension wear makes handling dangerous.

- Increased driver fatigue – Poor alignment makes trucks harder to control over long hauls.

A fleet we worked with ignored alignment issues for months—until they had to replace all four tires on multiple trucks, costing thousands in avoidable expenses.

Related: Fleet Tire & Suspension Maintenance

2. The True Cost of Ignoring Suspension & Alignment Issues

- Wasted Fuel: Misaligned wheels increase rolling resistance, forcing the engine to work harder and burn more fuel.

- Shortened Tire Life: A misaligned truck wears tires twice as fast, leading to premature replacements.

- Higher Repair Costs: Suspension damage gets worse over time—waiting to fix it leads to more expensive repairs.

One company we serviced saw a 15% increase in fuel efficiency after correcting their fleet’s misalignment—saving them over $50,000 annually.

How We Help:

- Computerized fleet alignment to reduce tire wear and fuel waste.

- Shock & strut replacements to improve driver comfort and control.

- Suspension system inspections to catch minor issues before they turn into major failures.

Related: Book a Fleet Alignment & Suspension Check

3. How Often Should You Check Fleet Alignment?

- Every 15,000 miles – Long-haul trucks should have alignment checked regularly.

- Every tire change – Ensuring new tires wear evenly.

- After hitting a pothole or curb – Sudden impacts can throw alignment off.

- If drivers report handling issues – Any complaints of pulling, vibrations, or rough rides should be investigated immediately.

A logistics company thought their trucks were fine—until they realized their fleet’s tires were lasting 40% less than expected. A quick alignment fix saved them tens of thousands in tire costs.

Related: Fleet Tire & Alignment Services

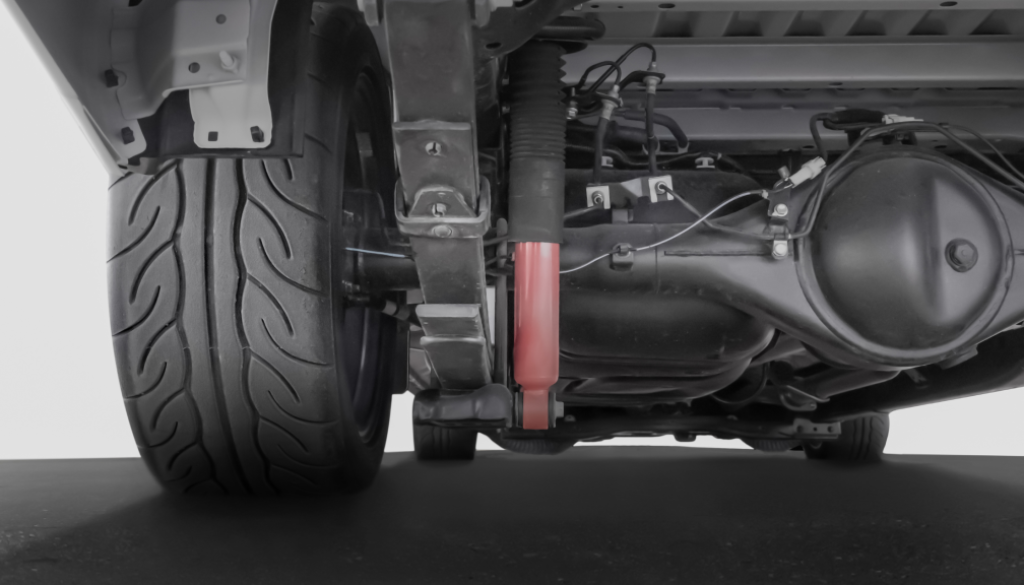

4. The Role of Shocks & Struts in Fleet Safety and Performance

Your fleet’s shocks and struts do more than just absorb bumps—they keep the truck stable, reduce brake distances, and improve steering control.

- Worn shocks increase stopping distances by up to 20%.

- Poor suspension leads to uneven weight distribution, stressing other components.

- Old shocks cause vibrations that increase driver fatigue and reduce productivity.

A fleet we worked with was experiencing excessive driver complaints about rough rides. After a full suspension overhaul, driver satisfaction improved, and their trucks performed better on long hauls.

How We Help:

- Suspension system inspections to detect worn shocks and struts.

- Shock absorber and strut replacements to restore ride stability.

- Air ride suspension checks for smoother, more efficient hauling.

Related: Fleet Suspension Repair & Replacement Services

5. Why Alignment & Suspension Issues Reduce Fleet Profitability

If your trucks aren’t properly aligned and maintained, your fleet is losing money—guaranteed.

- Higher fuel consumption from increased rolling resistance.

- Faster tire replacements due to uneven wear.

- Increased driver complaints from poor handling and ride quality.

- More frequent breakdowns leading to unexpected downtime.

A fleet manager we worked with thought his team was keeping up with suspension maintenance—until we performed a full fleet analysis and found multiple issues. After fixing them, his company saved over $75,000 annually in fuel and tire costs.

Related: How BFS Fleet Service Saves Fleets Money

6. Why BFS Fleet Service Is the Best Choice for Fleet Suspension & Alignment

At BFS Fleet Service, we help fleets reduce maintenance costs, extend vehicle lifespan, and improve efficiency with our expert suspension and alignment services.

- State-of-the-art computerized alignment diagnostics

- Full suspension system inspections & preventative maintenance

- Shock, strut, and bushing replacements for smoother rides

- Custom alignment schedules based on fleet usage

- Emergency repairs to minimize downtime

Next Steps:

- Book a Fleet Alignment & Suspension Check before it costs you thousands.

- Explore Our Full Fleet Maintenance Services.